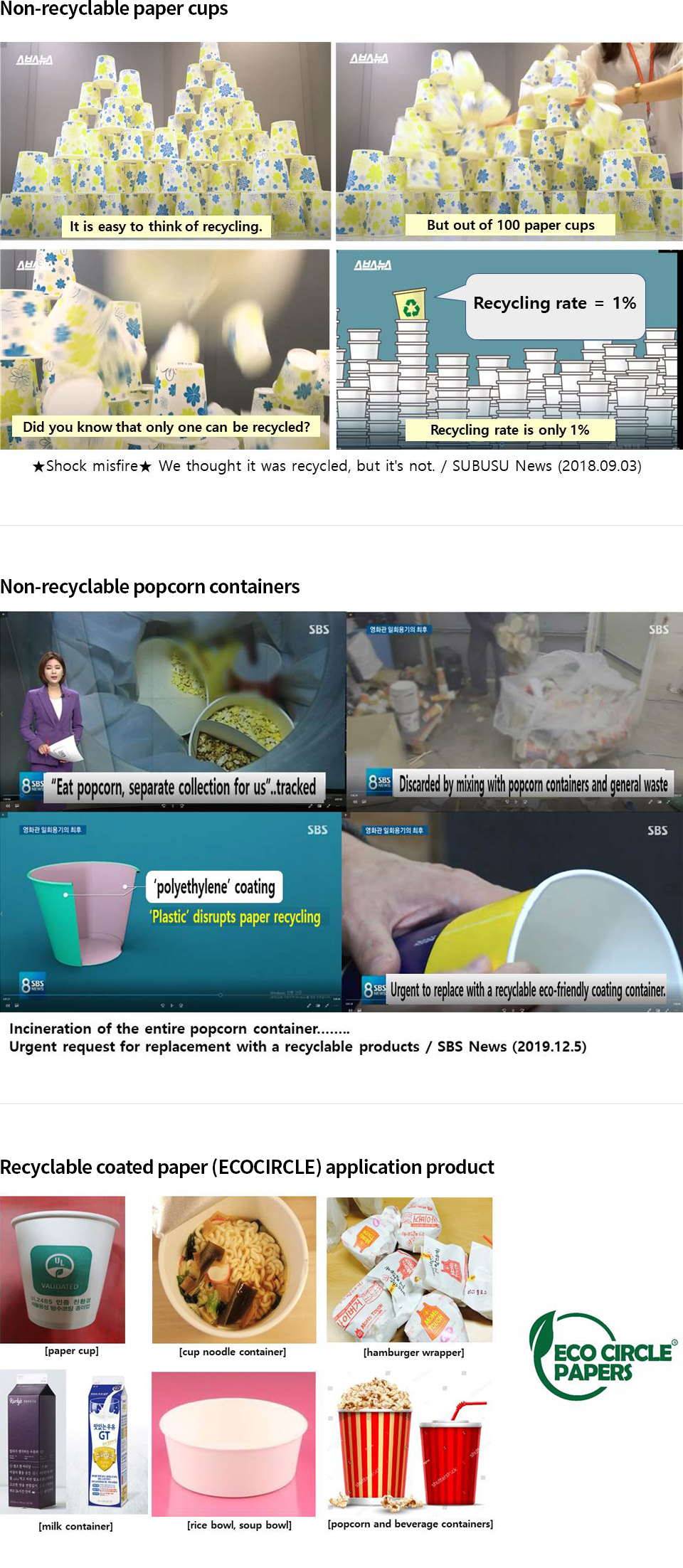

Product

Recyclable coated paper and container

ECOCIRCLE Product Features

-

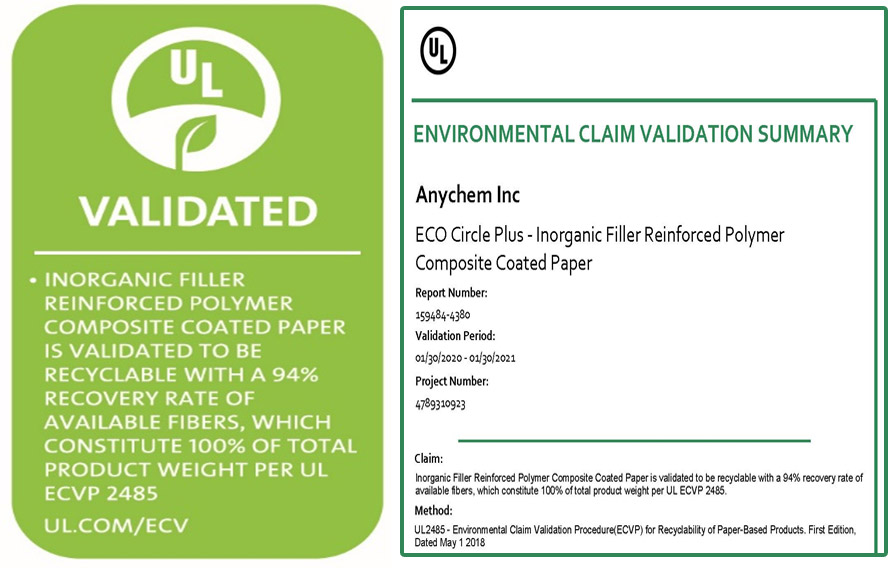

Excellent recyclability (pulp recovery)

UL 2485 (Evaluation of recyclability of coated paper) based on UL certification in the United States

-

Carbon-neutral response eco-friendly products

Prevention of carbon dioxide emissions during incineration through recycling

-

Excellent water and oil resistance

No squishy even after long storage

-

Excellent microwave cooking suitability (high heat resistance)

Suitable for food safety after microwave treatment

-

Excellent stain resistance

No red fat inside the container after eating

-

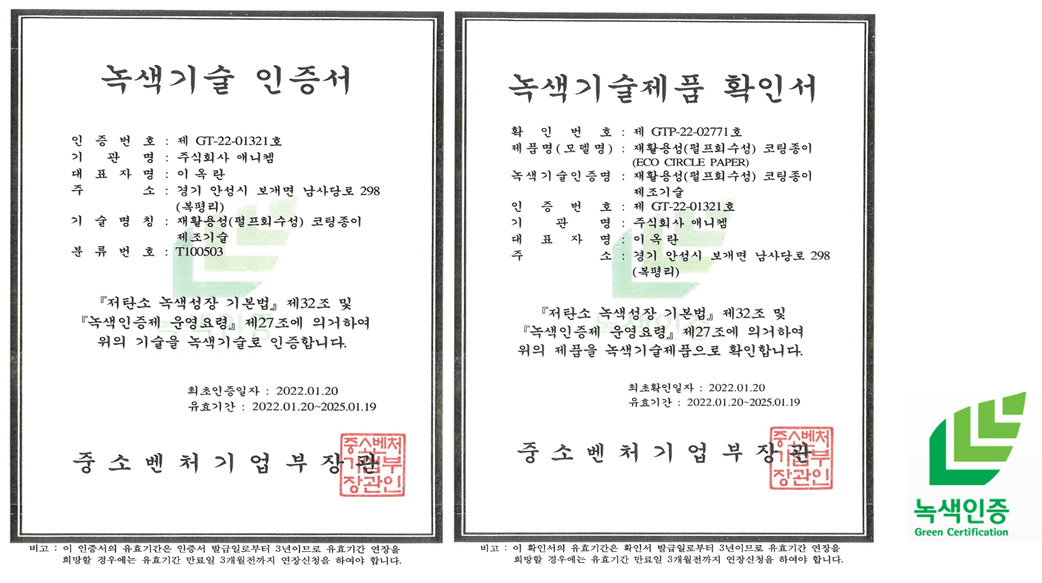

Green technology certification, patented product recognized for excellent technology

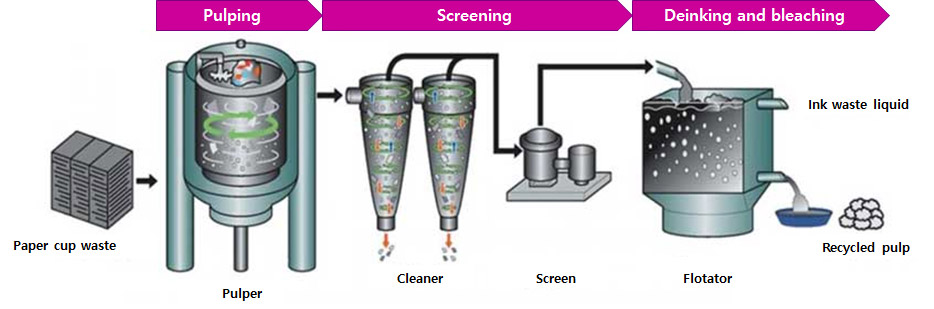

Paper waste recycling (pulp recovery) process

- Dissociation process

- - While impacting the coated paper waste with the impeller in the pulper (maintained at about 50°C), dissociate it with aqueous caustic soda solution and recover it as a slurry-type pulp (requires complete removal of the coating layer within 1 hour, which is economic

International standard for recyclability (pulp recovery) evaluation

- UL2485

- If the pulp is recovered after passing the dissociation process selected among the TAPPI 274, TAPPI 275, and TAPPI 278 standards and the amount of components (rejects) such as the coating layer removed is less than 15% by weight, it is judged to be recyclable (established in 2018)

Example of UL2485 recyclability determination according to composition and dissociation performance of coated paper sample

| Developed coated paper composition (wt%) | Composition after passing the dissociation process (wt%) | Pulp recycling yield (%) | UL2485 certified | ||

|---|---|---|---|---|---|

| coating layer | paper (pulp) | Rejects | pulp | ||

| 20 | 80 | 20 | 80 | 100 | fail |

| 13 | 87 | 13 | 87 | 100 | pass |

| 10 | 90 | 18 | 82 | 91 | fail |

Recyclability evaluation(ECO CIRCLE PLUS)

Recyclability evaluation by UL2485 certified organization FPInnovations (Canada)

| division | Developed coated paper composition (wt%) | Composition after passing the dissociation process (wt%) | Pulp recycling yield (%) | UL2485 certified | ||

|---|---|---|---|---|---|---|

| coating layer | paper(pulp) | Rejects | pulp | |||

| Inorganic filled polymer composite (new material) coated paper (developed product) | 6 | 94 | 6 | 94 | 100 | pass |

| Polyethylene coated paper (comparative product) | 8 ~ 13 | 87 ~ 92 | 25 ~ 35 | 65 ~ 75 | 70 ~ 80 | fail |

-

Polyethylene coated paper

The pulp dissociation rate is slow as the flexible polyethylene coating layer is attached within a short dissociation time. -

Developed new material coated paper

The pulp dissociation rate is very fast and cleanly removed as the coating layer of the hard inorganic material-filled polymer composite (new material) is broken within a short dissociation time

Waterproof and oil-proof

No leaks or squishy even after 1 hour after filling with water with ink

No oil leakage or squishy even after 1 hour after filling with cooking oil

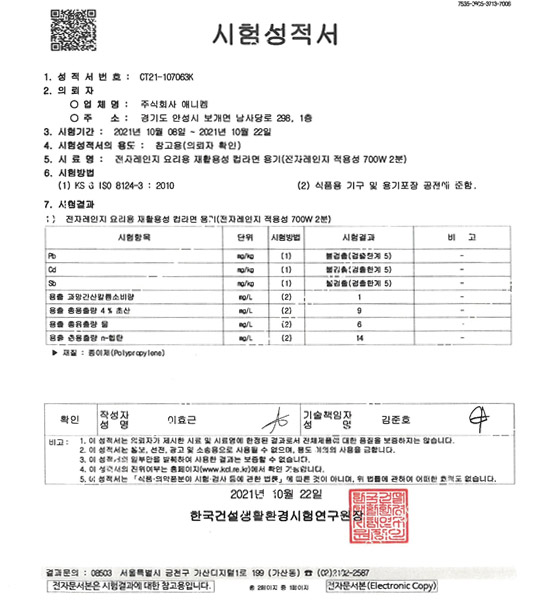

Microwave compatibility (heat resistance)

Food safety evaluation after processing paper containers at 700W in a microwave for 2 minutes

Heat-resistance/Stain-resistance

-

-

Low density polyethylene coated paper container (currently used product) Inorganic filled polymer composite coated paper container (Anychem)

Low density polyethylene coated paper container (currently used product) Inorganic filled polymer composite coated paper container (Anychem)Softening point(℃) Melting point(℃) Low density polyethylene 93 105 Inorganic filled polymer composite 150 170

Green technology certification

Relevant intellectual property rights

| Filing date | Registration number | Title | |

|---|---|---|---|

| Patent | 2018.08.24 | 10-2007974 | Oxidative biodegradable recyclable waterproof coated paper |

| 2018.10.11 | 10-2026231 | Tasteless odorless recyclable waterproof coated paper | |

| 2019.02.07 | 10-2006945 | Eco-friendly recyclable waterproof coated paper | |

| 2019.07.26 | 10-2140079 | Tasteless, odorless, biodegradable, recyclable, waterproof coated paper | |

| Trademark registration | 2019.08.27 | 40-2020-0060161 | ECOCIRCLE |